Product Design, The Balancing Act

When the Industrial Design phase is completed the product design phase can begin using the ID as a road map. Every Product Design effort must achieve a balance between: cost, performance, and manufacturability. It is very easy at this stage to start down the wrong path causing delay and extra cost. PEP Design offers skill, experience, and diligence to keep the integrity of the Industrial Design in place while simultaneously satisfying product design requirements.

Stage 1

The Design Phase

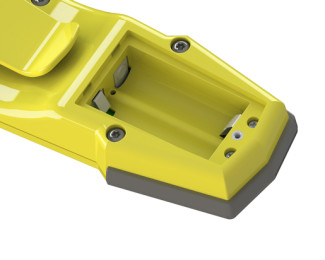

The design phase is about defining all part geometry and proving out form and function. Our philosophy at PEP Design is to simulate and prototype early and often to verify assumptions about how it will be made, and how it will be used. Simulation and prototypes are cheap; mistakes are expensive. “One good test is worth a thousand expert opinions.” — Wernher von Braun

Stage 2

Implementation

Once the product is fully designed, documented, and validated it is time to launch tooling. Whether this is for casting, molding, stamping, or forming, it involves a capital investment and a financial commitment. At this point, a product design engineer needs to be as careful, detailed, and precise as humanly possible. Our designs are thoroughly reviewed at multiple stages throughout the design process before being transferred into tooling.

Stage 3

Pre-production and Production

As a product starts to be manufactured in larger and larger volumes new challenges will be revealed. A different world is entered when manufacturing thousands compared with a few hand built prototypes. PEP Design is accustomed to providing support to make this transition as smooth as possible.

Stage 4

Current Products Support

Products continue to evolve and improve over their life cycle. Costs need to be lowered, scrap needs to be reduced, and quality needs to be improved. PEP Design can add value throughout the full life cycle of a product.