Patient Data Uplink

The Challenge

In today’s fast pace digital world, patient data is ever more frequently being automatically uploaded to a health care provider. However, many medical products on the market and in use today are only able to store patient data and still require the patient to visit a medical facility to download the data.

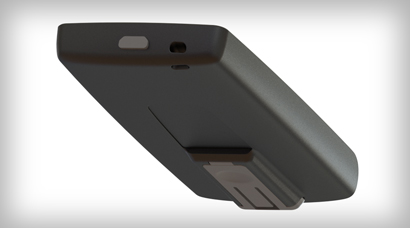

The device needed to be sleek and as small as possible since patients are already carrying one medical device and probably a cell phone as well.

While it is becoming more common for medical devices to have a GSM modem onboard to automatically upload patient data, there is a need for a bridging communication device to interface with existing products in the field that are not ready to be retired. The device needed to be sleek and as small as possible since patients are already carrying one medical device and probably a cell phone as well. The device needed to be durable, rugged, and able to be carried in a pocket, backpack, or clipped to the user’s belt.

The Solution

Pongratz Engineering was responsible for the plastic part design, PCB outline, and placement of components that interface with the plastic. Pongratz Engineering worked with the customer to evaluate several different product configurations and helped to narrow down and select the final form of the product. Snap locks were used to assemble the plastic case together without any fasteners, as requested by the customer.

An Electrical Engineering (EE) firm that Pongratz Engineering partners with was responsible for the PCB design, hardware and software design. A custom designed membrane switch was used to control the device (power button, LED indicators, etc.). Capacitive touch buttons were investigated, but it was thought that the higher force snap domes would lead to fewer accidental button activations. Special care was taken to ensure a RF transparent material was used to construct the case.

A rapid tooling aluminum mold was constructed to prove out the design and to speed the acquisition of actual plastic parts. These initial parts were used for testing, design verification, and clinical trials. A production steel tool was constructed later for high volume production.