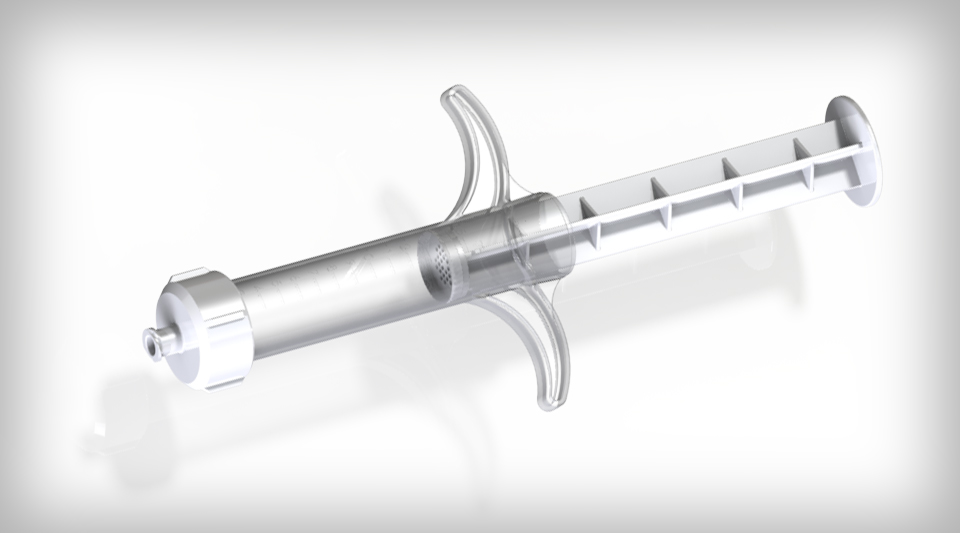

Bone Graft Delivery Device

The Challenge

A Minnesota medical company wanted an inexpensive, disposable, and simple method to mix up a bone chip and cement matrix. The bone graft mixture needed to be free of gas bubbles and easy to dispense. No tools could be used and just hand tightening strength could be employed to make the device work. The device needed to be made of bio-compatible plastic and molded in volume. Current competitor products require an expensive vacuum pump to evacuate all gas before the bone and matrix is mixed together.

By using a permeable membrane, Pongratz was able to create a cost-effective disposable bone graft injector at a greatly reduced cost.

This works well, but is cumbersome and not every facility has the correct vacuum pump available. A self-contained kit approach would give the product a competitive edge in the market.

The Solution

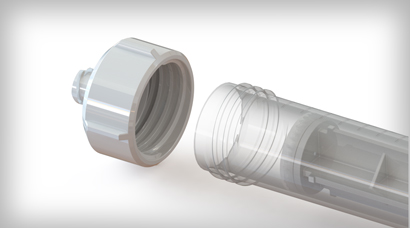

Pongratz Engineering developed a method that allowed gas to escape from around the bone chips but not let any of the liquid cement leak out. The method employed a gas permeable membrane to let gas escape but not any liquid. Once liquid touched the membrane it would “wet out” and become a liquid tight seal. The gas permeable membrane is located in the front face of the plunger, enabling gas inside the syringe body to escape as the liquid cement is injected from the front. Once the liquid cement fills up the syringe, the bone log is ready for use. The front cap can then be unscrewed and the plunger depressed to push out the bone graft material.

Pongratz Engineering developed the method of using the gas permeable membrane technique for this device. PTFE membranes have been used before as a gas vent seal but never used in this manner. Pongratz Engineering designed all the plastic parts and managed the tooling quote and build. The product was submitted and received FDA 510K approval.