Ross Zimmerman came to Pongratz Engineering with an idea. He explained that when moving a boat in and out of berth, drawing alongside another vessel, or other close maneuvers, having an instant visual reference of rudder angle is critical to preventing accidents. He was interested in creating a prototype of a new kind of rudder indicator. Currently there are two types of rudder position indicators on the […]

READ MORE ▶

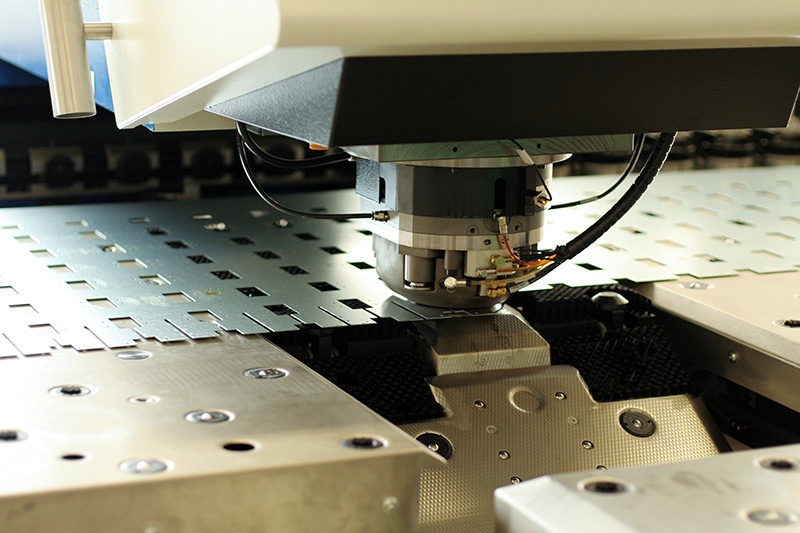

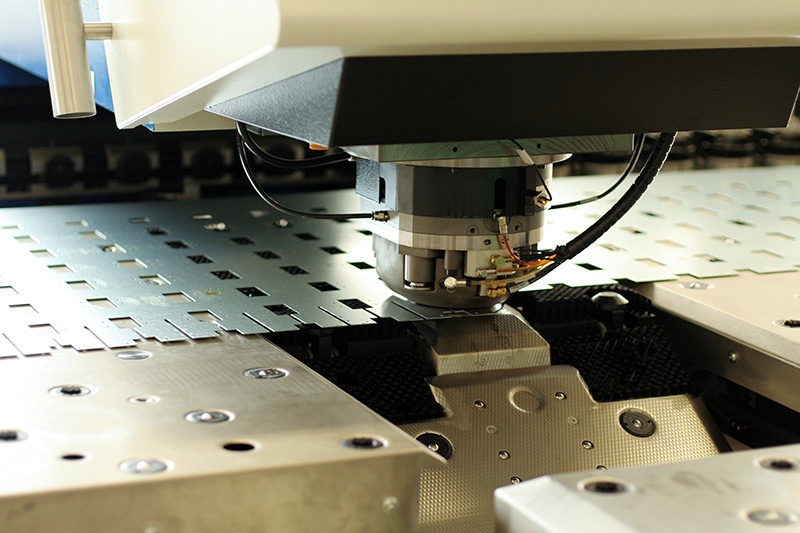

This next post in our series on high volume prototyping examines the Computer Numerical Control (CNC) Turret Punch Press, a technology that offers the option of punched and bent sheet metal for prototyping without the high tooling costs. The first manual turret punches were manipulated and moved by human hands. One had to have great familiarity with the press, as the correct tool must be selected for each operation. […]

READ MORE ▶

Thermoforming is a process that utilizes a heated thermoplastic sheet that is formed and then trimmed to create the final product. In order to do this, the plastic sheet or film is heated to a temperature just below the material’s melting point, which makes it pliable enough to follow features in the mold. The sheet is pressed down against the male plug, using […]

READ MORE ▶

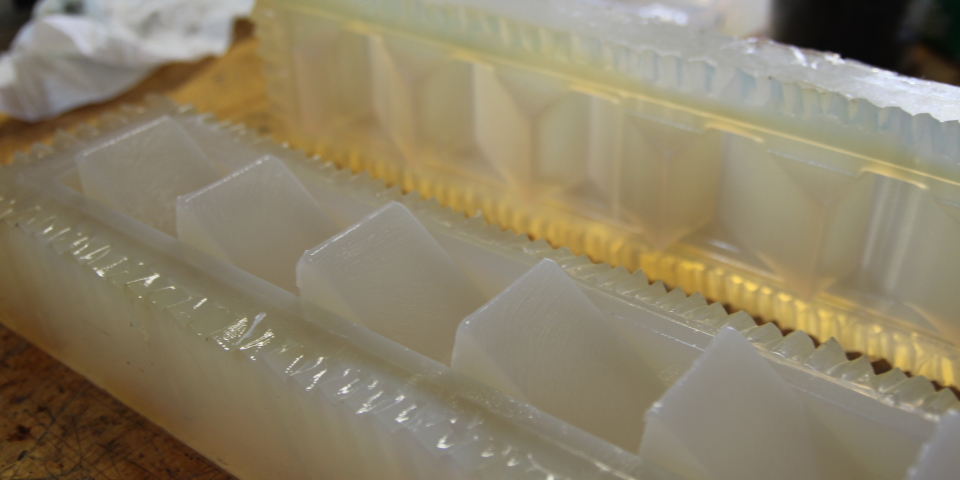

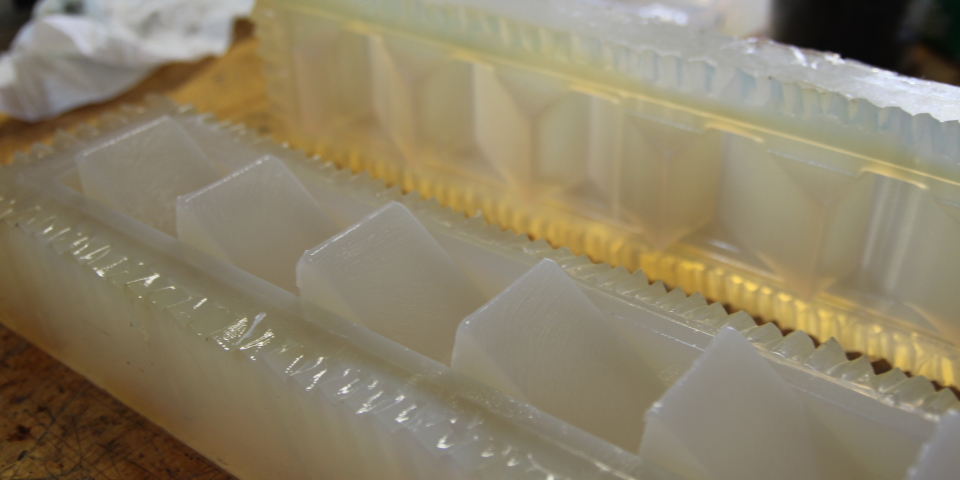

This series investigates the most cost-effective ways to fabricate prototypes in volume. When more than 3 to 6 prototypes need to be constructed, additive rapid prototype techniques become too costly. A mainstay technology that is frequently used involves constructing a silicone mold and using two-part urethane to cast the parts. This saves on cost because multiple parts can be cast from the same mold. Steps The […]

READ MORE ▶

This next post in our series on high volume prototyping examines Computer Numerical Control (CNC) machining, a technology whose virtues include precision and speed. The first vertical machining mills were manipulated and moved by human hands. In a CNC machining center, the cutting tool is moved using servo motors and computer software, which means once the program is set […]

READ MORE ▶

Plaster Mold Casting, or PMC, also known Rubber Plaster Mold (RPM) casting, is a process that utilizes a plaster mold to create cast metal parts. The technique has its place because the tooling is less expensive than production tooling, and the part price is less than using an SLS rapid prototyped part and investment casting. […]

READ MORE ▶

In this next series of blogs, we’ll look at high volume prototyping, the techniques involved, and why it is done. During a product development cycle, there are always different levels of prototype sophistication and volumes needed, depending on the product being developed. At the beginning the prototypes needed are simple and few in number because they are proof of concept—a reality check needed to make sure […]

READ MORE ▶

Stereolithography (SLA) is an additive manufacturing or 3D-printing technology that uses vat of liquid ultraviolet curable photopolymer resin and an ultraviolet laser to build parts one layer at a time. For each layer the laser traces the cross-section of the part onto the surface of the liquid resin. Once the liquid is touched by the […]

READ MORE ▶