This blog series explores 3D printing options that are available today.

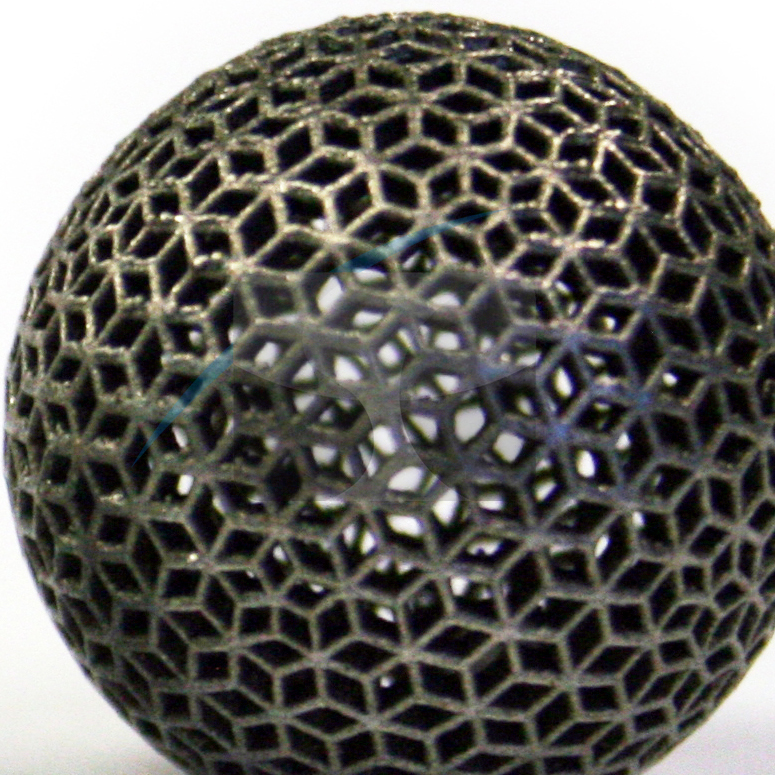

One of the more exotic and high-performance technologies available is Direct Metal Laser Sintering (DMLS). DMLS is a relatively new rapid prototyping process that uses a focused laser beam to fuse metal powder together layer by layer, creating a 3D model of the part. There are many benefits to using this process, but it does have its limitations.

Benefits

The first major benefit is that the end product is metal as opposed to a plastic part produced in other rapid prototyping processes. Currently DMLS can be done in stainless steel, cobalt chromium, titanium, and Inconel (a nickel-chromium based super-alloy). When printed, these materials have strengths that can be up to 90% of the strength of a machined part, which is astonishing when compared with other 3D printing technologies.

In some cases, such as smaller complex parts, DMLS can be cheaper and faster than standard machining. This is because the parts are done in one build, layer by layer. The same part in traditional machining may have 3 or 4 different machining setups or operations to get to the final product.

After the part comes out of the DMLS machine, it can be finished in a variety of ways. The part can be left as it is (unfinished) or abrasive blasted (standard), shot peened, polished, or even CNC machined. Also, parts produced via DMLS can be heat-treated for either stress relief or age hardening. This flexibility greatly enhances how the parts can be used.

Limitations

The limitations at this point in the technology are size and cost. Long and skinny parts have a tendency to warp or bend in the building process, producing inferior parts. Also simple parts that can be machined will likely cost less than a DMLS part. Internal voids are also more likely to happen with DMLS compared with traditional metal machined parts. DMLS as a choice really makes sense when the parts are geometrically complex, small in size, and not many parts are needed.

Pongratz Engineering is routinely called upon to recommend and select rapid prototyping methods for our customers. Contact us for more information or professional advice, www.pongratz-engineering.com.

NEXT UP: PolyJet

Related posts: