What is Fused Deposition Modeling (FDM)?

The first technique we’ll examine is Fused Deposition Modeling (FDM), one of the most popular rapid prototyping technologies at the moment. It has been referred to as the “workhorse” of the 3D printing world. FDM is an additive manufacturing technology, meaning it builds up a part layer by layer. Even though FDM technology is used frequently, it’s not necessarily ideal for every prototyping application.

FDM might be the best option if the part to be built is of a reasonable size (smaller than a bread box) and has features larger than 0.020”. FDMs also work for marketing purposes and are even employed for low volume production, but typically they are used to test form, fit and function, or to show an initial concept.

Some considerations

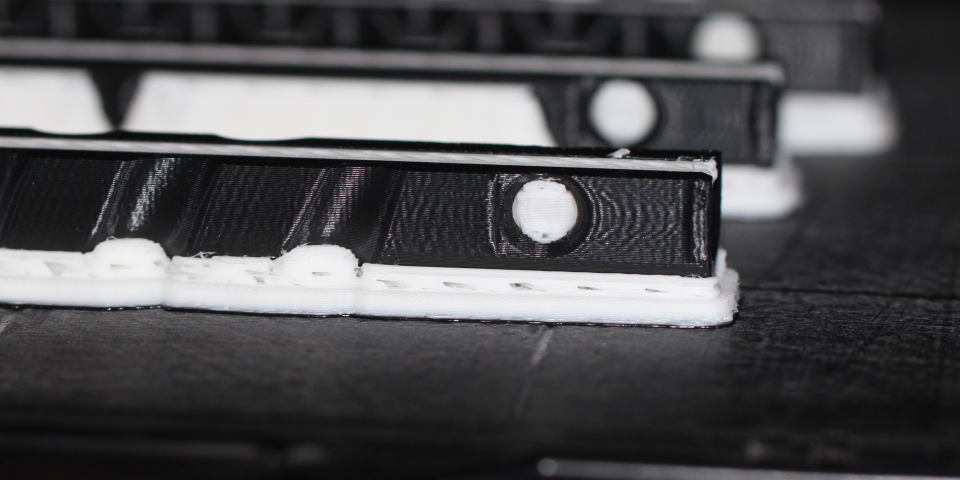

FDM parts are made of thermoplastic resin. The build material is heated and extruded out a small nozzle in a fine bead like a caulk gun to build up the part. The molten plastic immediately solidifies after being extruded onto the model surface. The most common FDM material is ABS, but other materials used include polycarbonate, polyamides, and polystyrene. Because the parts are extruded layer by layer, these prototype parts are about half the strength and half the stiffness of the final injection molded parts. Each FDM machine is rated for different tolerance variations, but most commercial FDM machines can hold tolerances of ±.007”. This tolerance may increase to .010-.013” for larger parts.

Pros and cons

FDM has the benefit of being one of quickest rapid prototyping technologies. Most shops can turn around FDM parts in just a few days, depending on quantity and size. Unlike cast parts or injection molded parts, FDM parts have relatively no geometry limitations except for building very small features. This makes FDM ideal for parts with complex geometry and undercuts. However, since the part is built in layers, curved surfaces have visible steps in the finish. Also, if your parts are very large, you may need to break them down into several parts to fit them onto the build tray. This means final parts would have visible breaks where parts are solvent bonded together.

Using FDM technology is an everyday occurrence at Pongratz Engineering. We have owned an FDM machine since we began business in 2006—we literally cannot live without it. Please contact us if you have questions or prototyping needs at www.pongratz-engineering.com.

NEXT UP: Direct Metal Laser Sintering (DMLS)

Related posts: