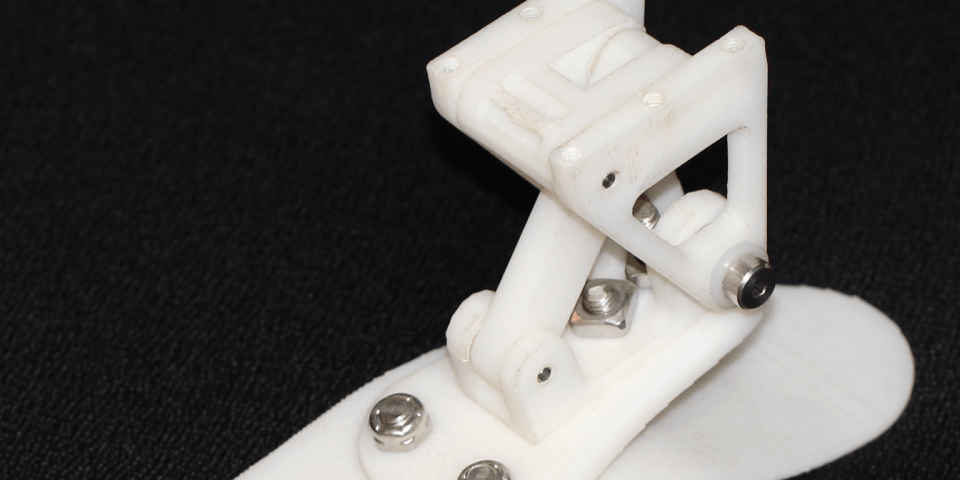

3D printing … Yes, it is likely you have heard the term by now. The term is starting to be used like “Xerox” or “Google”. In the engineering and product-design world, 3D printing is also known as rapid prototyping. Engineers use it to validate designs, make work-holding fixtures, and even for low-volume manufacturing. There are many different types of 3D-printing technologies to choose from, (SLA, FDM, DMLS, or SLS), and they all have their unique strengths and weaknesses. The differences include accuracy, material properties, cost, and speed.

Considerations

In this next series of blogs, we will report on each of the rapid prototyping technologies available and investigate the costs, merits, and deficiencies of each approach. Generally there is no silver bullet—no single technology to use in all situations. Every product-design effort is unique, and usually the size and geometry of the parts involved affect which rapid prototyping technology fits best. For example, the dimensional tolerance for a large part often doesn’t need to be as accurate as the tolerance for small part. Typically the more dimensionally accurate a part needs to be, the more expensive it will be. Another factor driving the cost is the amount of material used to build the part. The larger the part is, the more it will cost to build it. Given these two factors, a lower cost and less dimensionally precise method can be chosen for large parts.

Choose Carefully

Many factors come into play when deciding which prototyping technology to use. The rapid prototyping technique you choose can be crucial to the time line, cost, and ultimately success of a project. Practically every project that a product-design service provider works on will have an aggressive schedule and an expected low error rate (really I mean perfection). This reality makes the use of 3D printing for nearly every project a necessity—getting an actual part in your hand can’t be beat. Simply put, the technology is here to stay, and its use will only increase.

Pongratz Engineering is routinely called upon to recommend and select rapid prototyping methods for our customers. Contact us for more information or professional advice (info@pongratzengineering.com or 612-384-0122).

Related posts: